What are the common structures of Marine diesel engine parts and Marine sprockets

1. Overall structure

It is generally applied to the processing of single and double row, single and double flange sprockets with standard chain P=38.1 or less.

2. Welded structures

It is mainly applied in the processing of medium and large-sized single and double flange sprockets. During processing, the flange part is turned into a convex shape using bar stock turning. The gear ring part can be made by cutting the sheet metal and processing the outer diameter and shaft hole. A welding bevel is machined at one end of the hole and inserted into the flange part for welding. When welding, both ends should be welded, and low-hydrogen electrodes such as T506 electrodes should be used.

3. Cast sprockets

It is mainly applied in the processing of large sprockets. During processing, only the two end faces of the gear ring and flange, the outer diameter and inner diameter, and the keyway are processed, and then the tooth profile is processed. The rings and sprockets are all cast. There are generally two types of materials for casting sprockets: cast iron and cast steel such as HTl5O, HT2O0 and ZG310-570(ZG45).

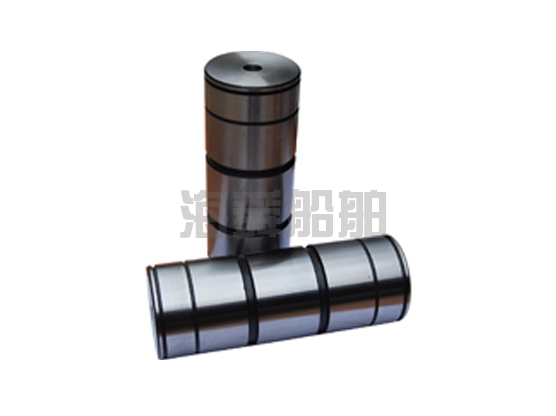

4. Forged sprockets

It is mainly applied in the production of medium and large-sized sprockets that are subjected to greater forces. During forging, whether it is a single flange type or a double flange type, it is generally forged into a convex shape, and sufficient machining allowance is left for the shaft hole.