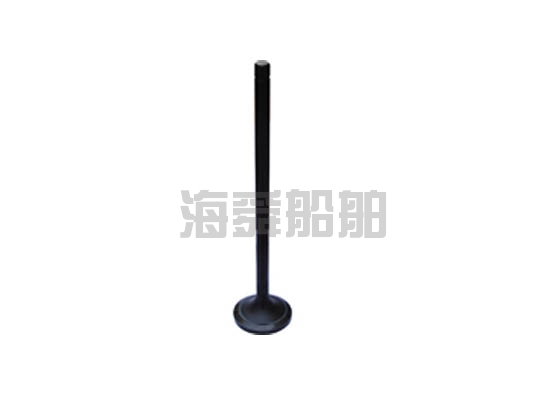

Causes of failure of exhaust valve of marine diesel engine parts

The working conditions of the exhaust valve in marine diesel engines are very harsh. The bottom surface of the valve is in direct contact with high-temperature combustion products, and it is also subjected to high temperature (900~1000℃) and high speed of corrosive gas (up to 600m/s) during the opening of the valve. For scouring, the center temperature of the valve is as high as 700-800℃, and the temperature in the middle section of the transition arc between the valve disc and the valve stem is also 600-700℃, as shown by the working temperature of the exhaust valve. Too high temperature will reduce the mechanical properties of the metal material, and the material will be thermally deformed. When the valve surface is not tightly sealed, it will cause the high temperature gas to burn the valve surface. When the valve is seated, under the combined action of the inertial force of the valve and the valve seat and the force of the spring, it also bears a considerable impact alternating load. When the valve bounces or the valve gap increases or increases, this load will obviously increase. The collision between the valve and the valve seat can easily cause deformation and severe wear of the sealing surface. Since most marine marine diesel engines are supercharged marine diesel engines, the fresh air pressure in the intake duct prevents the possibility of obtaining lubricating oil from the valve duct, so dry friction between metals is prone to occur. However, there is always a layer of lubricating oil or smoke oil between the gas valve of general marine diesel engine and the alloy surface of the exhaust valve seat of supercharged marine diesel engine. In addition, wear occurs between the valve stem and the pipe, and the top and end of the valve stem are impacted and worn by the rocker arm. The exhaust gas and the piston crown form deposits, causing the so-called "high temperature corrosion".

So far, there is no economically reasonable process to remove and remove corrosive elements from residual oil. Even high-grade alloy steel and surfacing exhaust valve steel are also corroded by fuel oil. Violating the vehicle maintenance regulations during the operation of marine diesel engines, starting the marine diesel engine at low temperature and forced loading at low temperature, the combustion temperature of the marine diesel engine cylinder changes sharply. Under the load state of the marine diesel engine, the handle position is changed sharply, which deteriorates the combustion state of the marine diesel engine cylinder and causes a lot of fog. Poorly modified coarse heavy oil particles are injected into the cylinder, causing serious afterburning and incomplete combustion. Serious carbon deposits make the surface of the exhaust valve valve line also be contaminated by carbon deposits, and even cause difficulty in starting the main engine. This becomes the next time The oil head and exhaust valve failures of the main engine shortly after the start of the operation are hidden dangers. Therefore, these bad habits of manipulating and maintaining the marine diesel engine are also factors that cause the failure of the marine diesel engine valve.